ULTRASONIC MACHINING:-

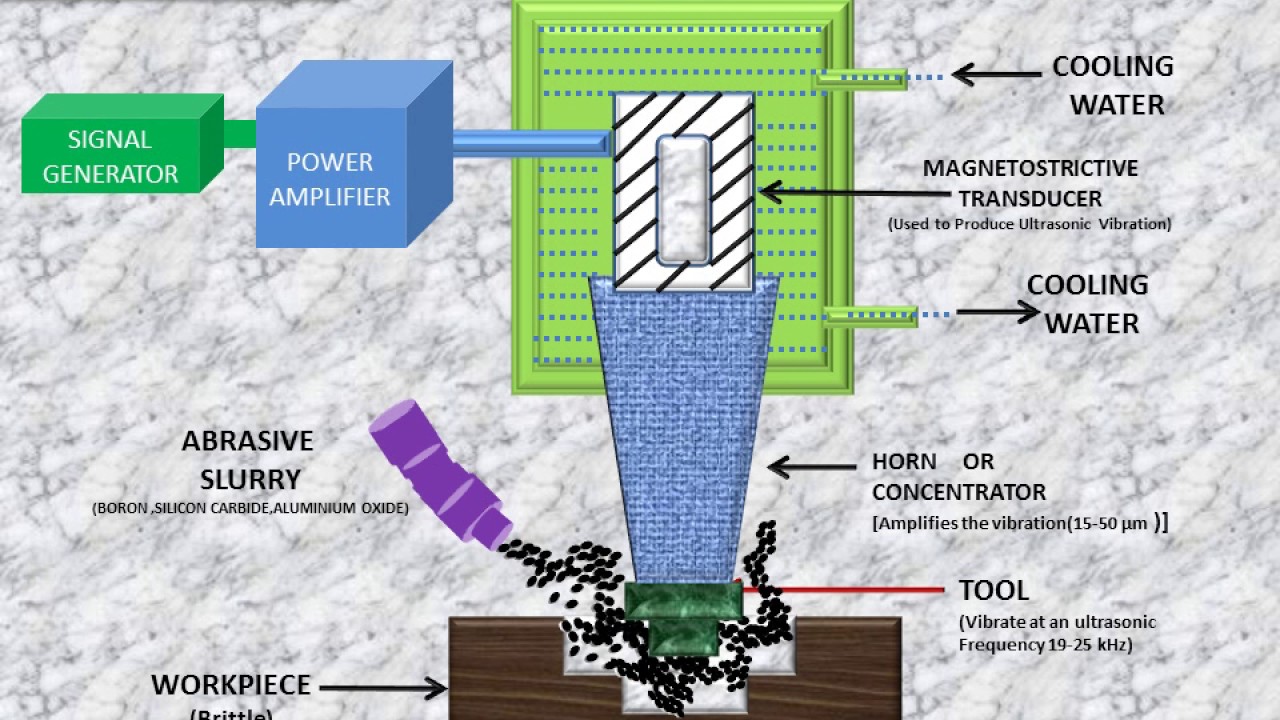

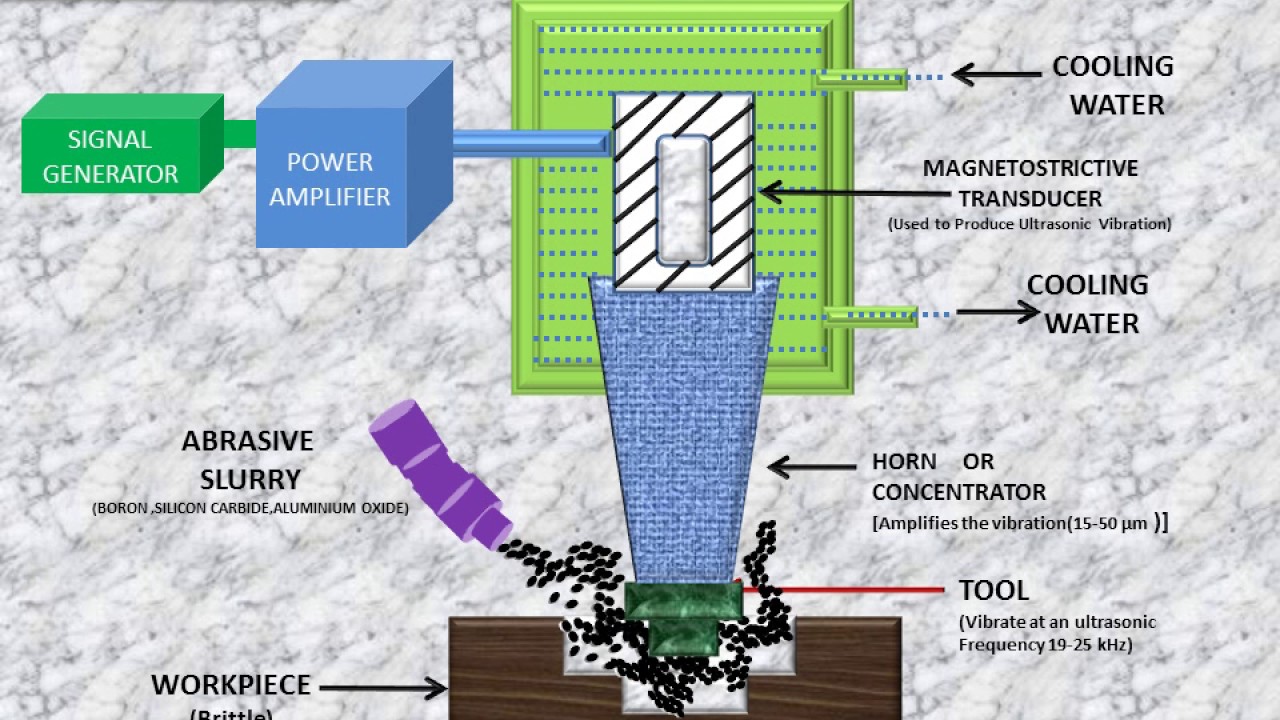

Ultrasonic machining, or strictly speaking the "Ultrasonic vibration machining", is a subtraction manufacturing process that removes material from the surface of a part through high frequency, low amplitude vibrations of a tool against the material surface in the presence of fine abrasive particles.

The tool travels vertically or orthogonal to the surface of the part at amplitudes of 0.05 to 0.125 mm (0.002 to 0.005 in.). The fine abrasive grains are mixed with water to form a slurry that is distributed across the part and the tip of the tool.

The tool travels vertically or orthogonal to the surface of the part at amplitudes of 0.05 to 0.125 mm (0.002 to 0.005 in.). The fine abrasive grains are mixed with water to form a slurry that is distributed across the part and the tip of the tool.

Typical grain sizes of the abrasive material range from 100 to 1000, where smaller grains (higher grain number) produce smoother surface finishes .....

Abstract

Ultrasonic machining, or strictly speaking the "Ultrasonic vibration machining", is a subtraction manufacturing process that removes material from the surface of a part through high frequency, low amplitude vibrations of a tool against the material surface in the presence of fine abrasive particles.

The tool travels vertically or orthogonal to the surface of the part at amplitudes of 0.05 to 0.125 mm (0.002 to 0.005 in.). The fine abrasive grains are mixed with water to form a slurry that is distributed across the part and the tip of the tool.

The tool travels vertically or orthogonal to the surface of the part at amplitudes of 0.05 to 0.125 mm (0.002 to 0.005 in.). The fine abrasive grains are mixed with water to form a slurry that is distributed across the part and the tip of the tool. Typical grain sizes of the abrasive material range from 100 to 1000, where smaller grains (higher grain number) produce smoother surface finishes .....

Abstract

Ultrasonic MachiningHard Brittle Materials and Other Challenges

As we all know machine tool, cutting tool, automation and software technology are all advancing. However, one other area of progress affecting manufacturers in ever-greater numbers is the advance of material technology. Machine shops are increasingly being challenged by advanced materials, including composites and hard metals, many of which are difficult to machine.

Traditionally used with abrasive cutting tools, ultrasonic machining is now an option for defined-cutting-edge milling and drilling tools as well. With these tools, ultrasonic’s advantages extend to its aid to chip breaking

Find a professional ultrasonic assisted machining for your application ?

Click Altrasonic Assisted Machining to realize it !

No comments:

Post a Comment