DEFINITION OF MACHINING PROCESSES : -

Machining is any of various processes in which a piece of raw material is cut into a desired final shape and size by a controlled material-removal process. ...Machining is a part of the manufacture of many metal products, but it can also be used on materials such as wood, plastic, ceramic, and composites.

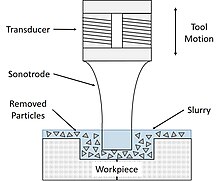

The tool present in the machine for cutting the materials is made from a soft material as compared to the work piece. The tool is usually made from materials such as soft steels and nickel. When the tool vibrates, the abrasive slurry (liquid) is added which contains abrasive grains and particles. The abrasive slurry is added till the work pieces interacts with the grains. Due to the particles of liquid added, the work brittleness of the work piece abrades the surface meanwhile the tool deforms gradually.

The time spent on ultrasonic machine entirely depends on the frequency of the vibrating tool. It also depends on the size of grains of the abrasive slurry, the rigidity and the viscosity as well. The grains used in the abrasive fluid are usually boron carbide or silicon carbide as they are rigid than others. The used abrasive can be carried away easily if the viscosity of the slurry fluid is less.

Ultrasonic machining

Ultrasonic machining, or strictly speaking the "Ultrasonic vibration machining", is a subtraction manufacturing process that removes material from the surface of a part through high frequency, low amplitude vibrations of a tool against the material surface in the presence of fine abrasive particles. The tool travels vertically or orthogonal to the surface of the part at amplitudes of 0.05 to 0.125 mm (0.002 to 0.005 in.).The fine abrasive grains are mixed with water to form a slurry that is distributed across the part and the tip of the tool. Typical grain sizes of the abrasive material range from 100 to 1000, where smaller grains (higher grain number) produce smoother surface finishes.Ultrasonic vibration machining is typically used on brittle materials as well as materials with a high hardness due to the microcracking mechanics.

Components of AJM process:

The figure shows the overall layout of the AJM process. The stream of gas is passed into the hose where the gas stream is passed. The velocity of the abrasive stream that is ejected from the nozzle is upto 330m/sec.

No comments:

Post a Comment